Near-Future

This video shows an animation of how the near-future sneaker concept works both as a product and as a service.

Future Sneaker

I made this project during Protohype, a Masters-level product design course at AHO. The course focuses on using design methods for sustainability and radical change; we are encouraged to speculate on the best possible future and design for that goal, instead of designing for incremental changes.

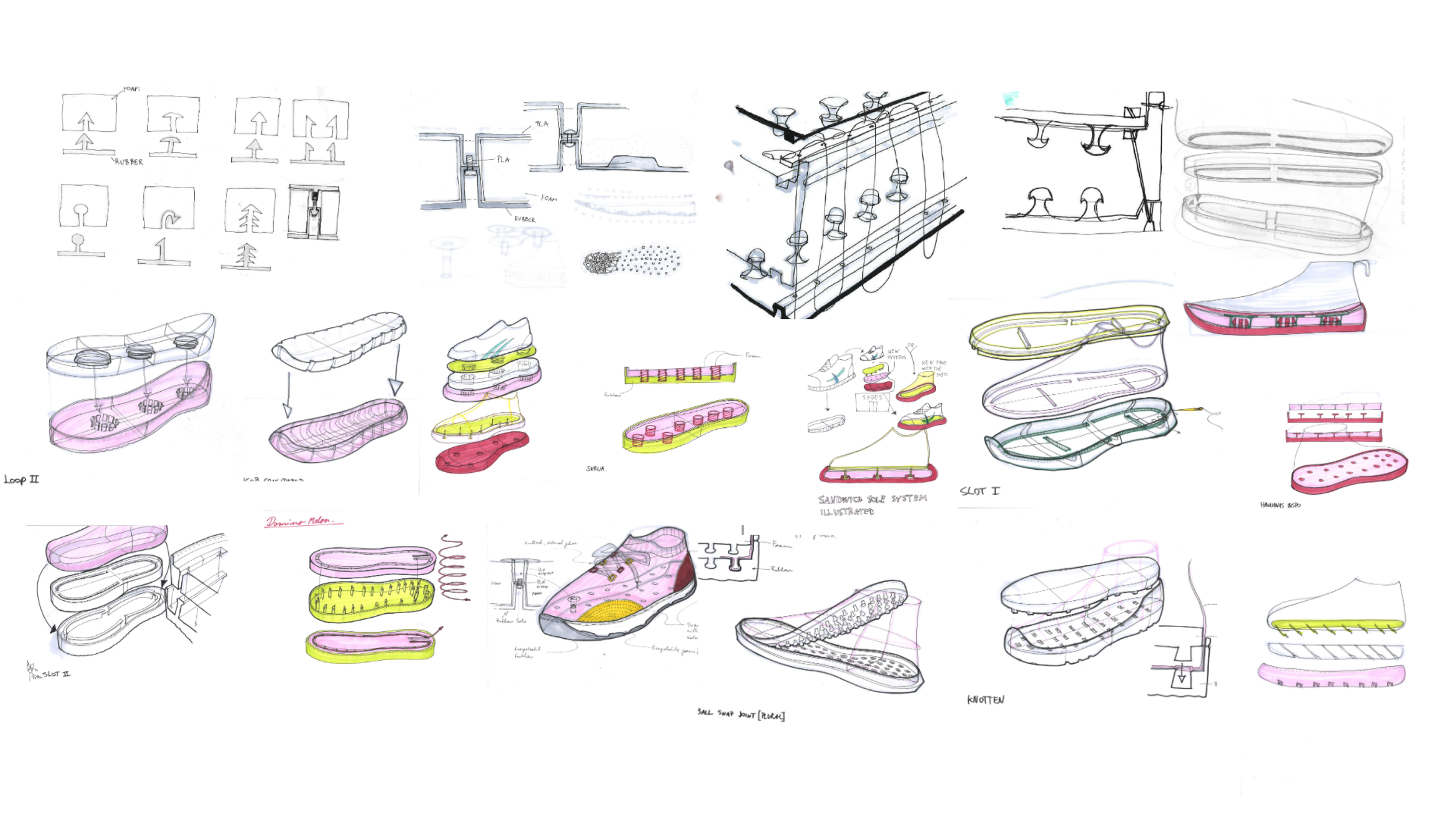

For this project, I wanted to explore how to avoid using glue as adhesion in sneakers. Without glue, it would be easier to separate the parts for repair, and to recycle the different materials after the end of the product’s lifetime.

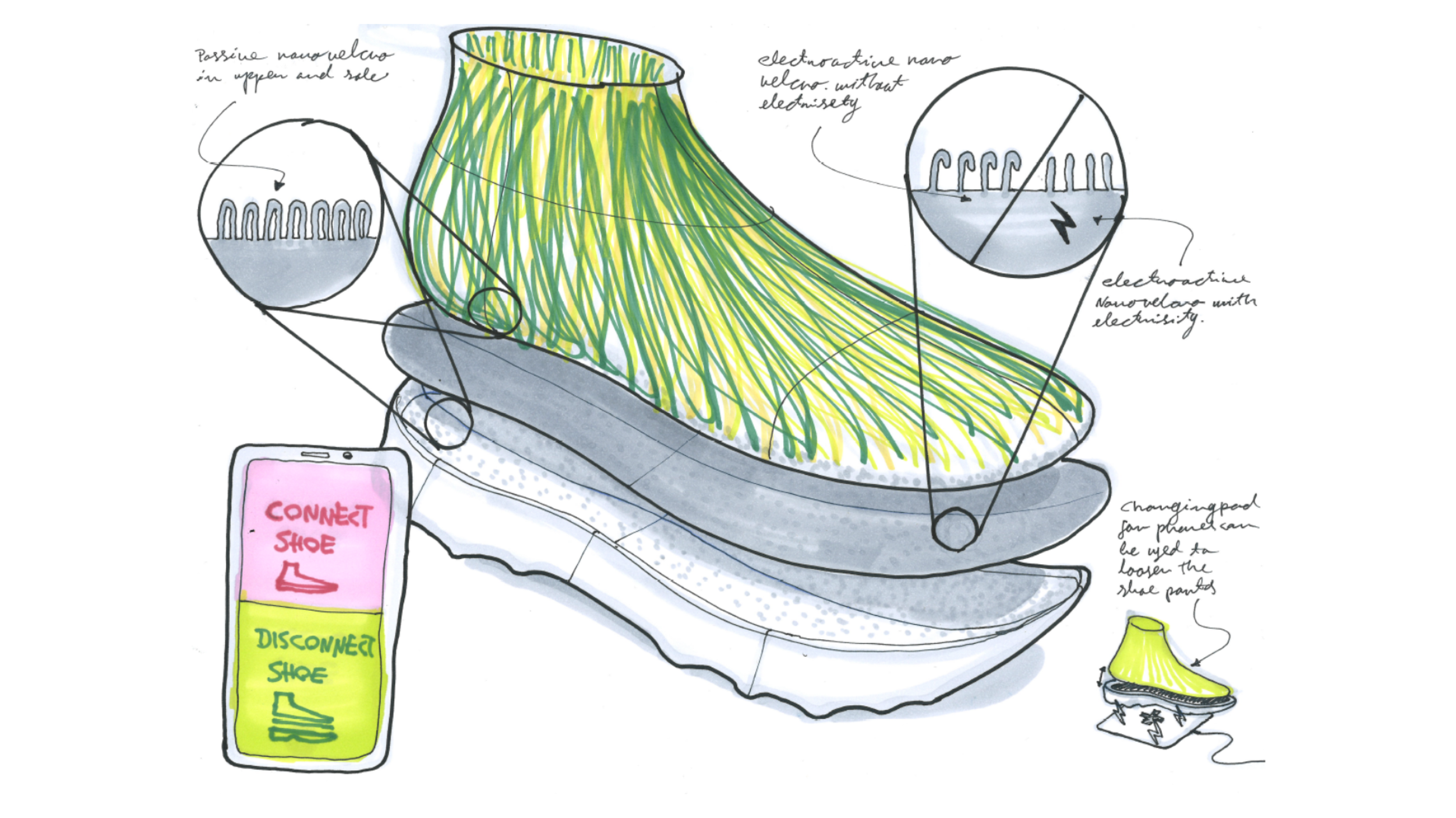

I developed a far-future concept and a near-future concept inspired by the far-future concept. For the far-future concept, I drew from existing trends to design a radically different adhesion technology called electroactive nano velcro, and designed a sneaker using this adhesive.

For the near-future concept, I designed a sneaker that could be made using today’s technology, but using mechanical adhesion instead.

For both projects, I also developed service design elements.

Project by: Jacob Pettersen

Project length: 3 months

AHO course: Product Design - Protohype, Spring 2019

Service

This is a Service Map of the near-future sneaker service. The central concept is that if a part wears out, you can order a new one online, or bring it to a repair shop where that part can be quickly replaced and the worn part recycled.

Process

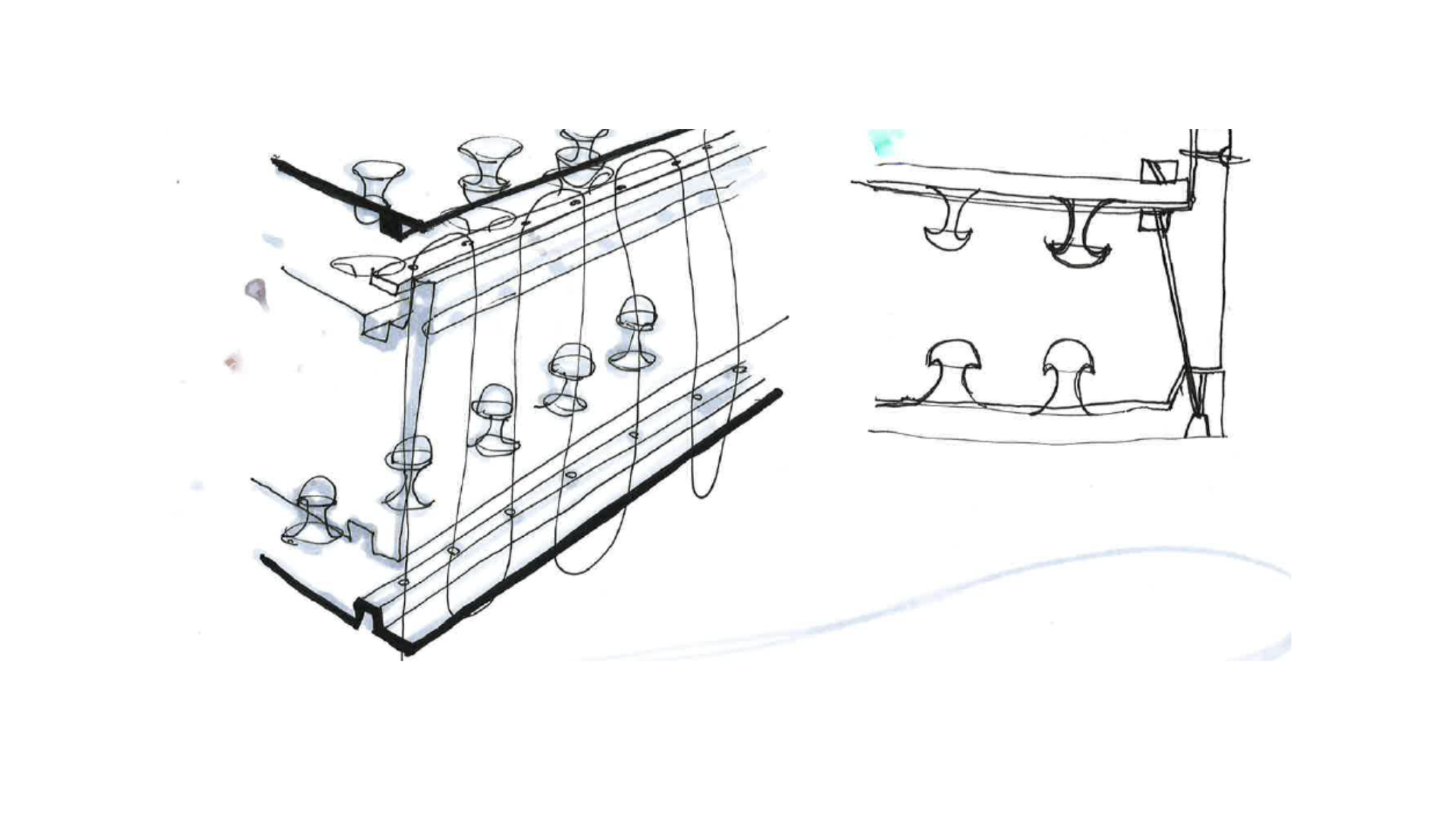

To produce the near-future sneaker, I analyzed existing sneakers and their construction. I also mapped out all the different way two parts could stick together through mechanical adhesion.

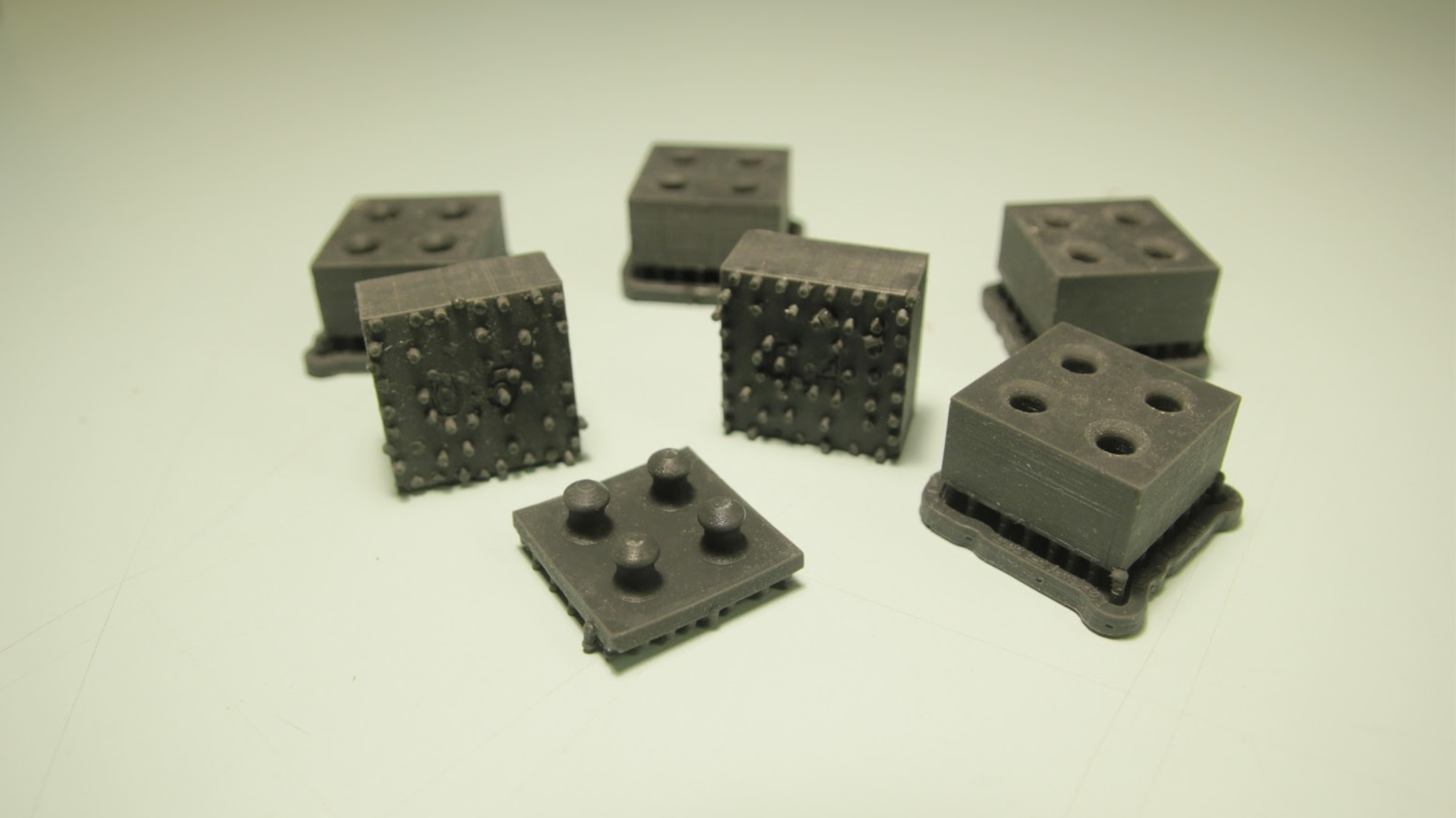

Based on these explorations, I drew sneaker concepts and 3D printed 1:1 samples of those mechanical adhesions. I opted for a snapfit and thread combination, as this seemed to be the most secure solution while also keeping it easy to attach and detach the parts.

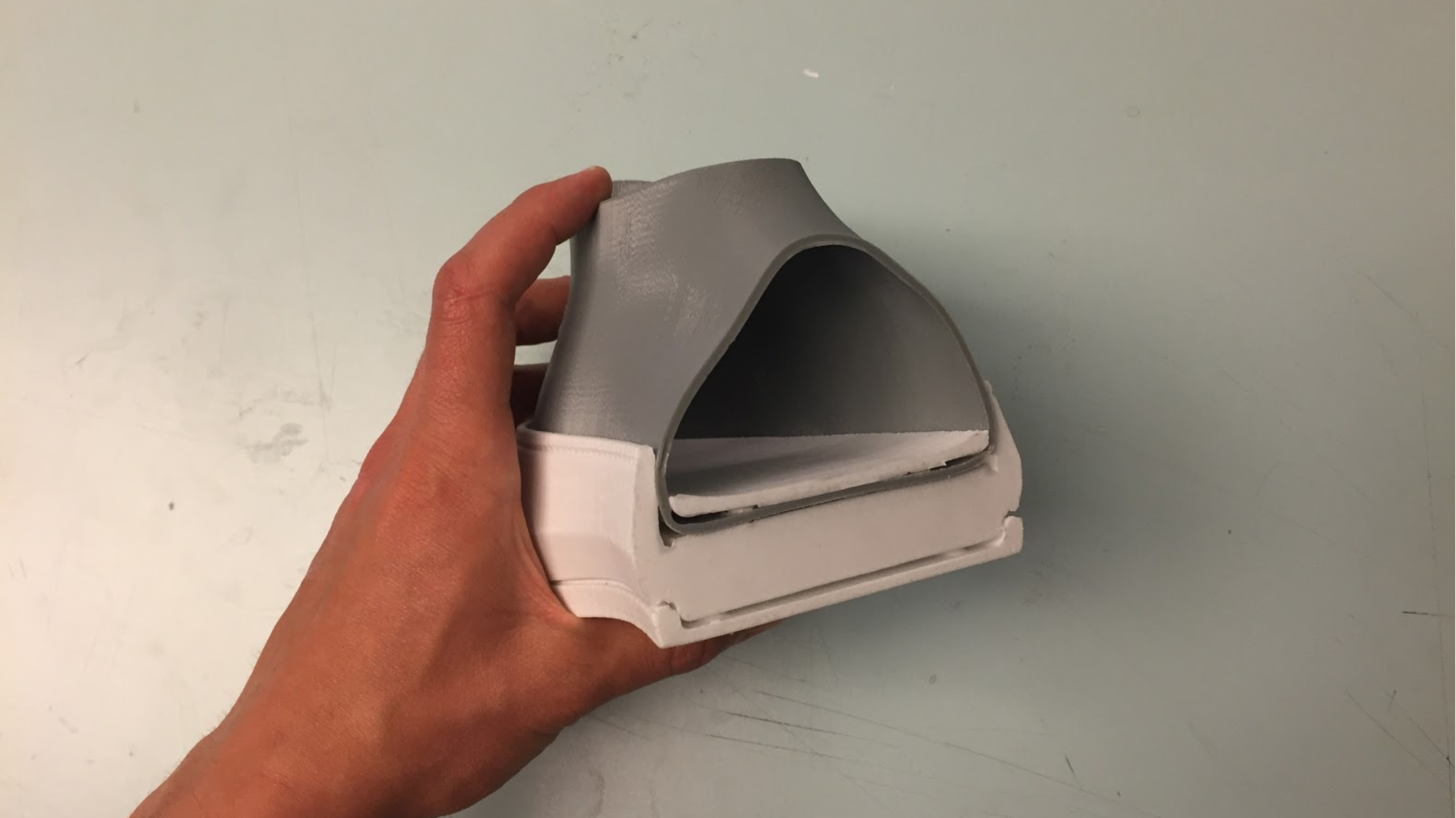

Finally, I ordered a 1:1 3D print of the sole in flexible TPU. The snap function worked, but the holes were too tight to thread it. With more resources, I would have printed a second iteration.

Far-Future

In the far-future concept, the sneaker user owns many different sneaker parts instead of many sneakers.

Parts are attached through electricity, using a charging pad and your phone as an activator. The adhesive is electro active velcro.

The goal with this concept was to decrease the number of sneakers people purchase, and to allow the different parts to be separately replaced and recycled.

Service

I imagined that the ideal future sneaker service would involve locally-produced sneakers made of local materials grown with microbiology. This material could be degraded into new material, and printed and knitted into new sneakers.

Through this service, we would reduce transportation and material waste, and a circular economy would finally be possible. The style of every sneaker would be specific to every city, because resources would be spent on shoe design instead of shoe manufacturing.

Process

The process for the far-future was based on developing an understanding of what would be an ideal sneaker industry for the environment. I understood that I needed technology that could support such a service, and found research on nano-velcro and electo active materials.

I also needed to understand how to mould soles and stitch and form uppers. The molding-forms you see in the photo was designed by me and printed on an Ultimaker 3D-printer. For moulding the soles I used two component TPU, and for the uppers I used textiles I purchased in London, which I heated over a last to create a stiff sneaker upper.